Biomaterials

Biomaterials are intended to be used as medical devices in contact with biological tissues and range from contact lenses to prosthetics for hip replacement. In our department we work on a broad range of biomaterials; from polymers and composites to ceramic to metals. Research on biomaterials is also strictly connected to tissue and regenerative engineering as well as drug delivery. We have expertise in these areas: we build different types of scaffolds and gels that not only accommodate cells inside but also influence their responses. We also build gels or nanoparticles that can deliver drugs at specific locations, on-demand.

Biomaterials are intended to be used as medical devices in contact with biological tissues and range from contact lenses to prosthetics for hip replacement. In our department we work on a broad range of biomaterials; from polymers and composites to ceramic to metals. Research on biomaterials is also strictly connected to tissue and regenerative engineering as well as drug delivery. We have expertise in these areas: we build different types of scaffolds and gels that not only accommodate cells inside but also influence their responses. We also build gels or nanoparticles that can deliver drugs at specific locations, on-demand.

|

|

|

|

|

|||

| Marta Cerruti |

Showan Nazhat |

Sidney Omelon |

Mihriban Ozden Pekguleryuz |

Stephen Yue |

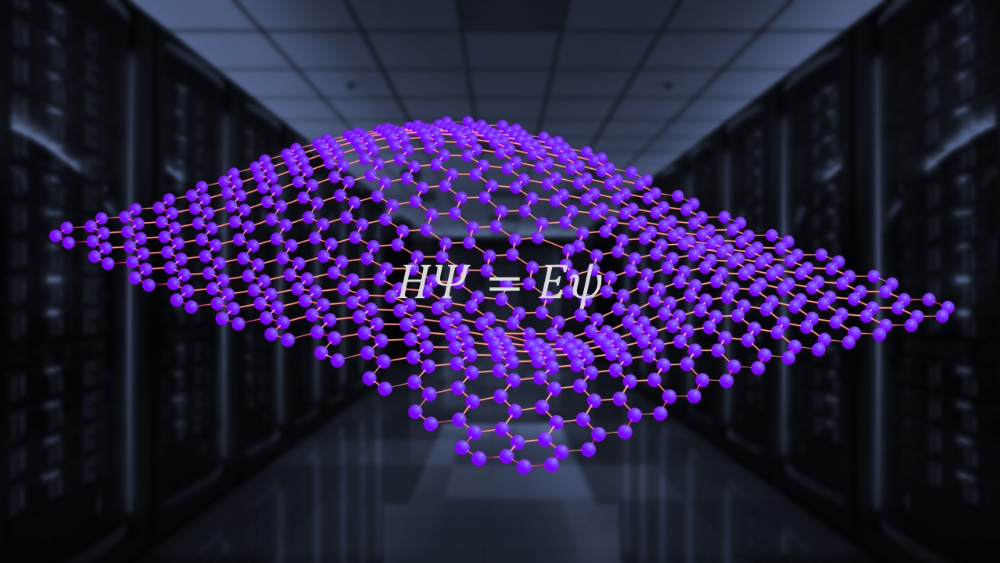

Computational Materials Engineering

Computational methods are becoming critical in all areas of science and engineering, such as Density-Functional Theory calculations and multiscale modeling, offering insights into material behaviors at the atomic, microscopic, and macroscopic scales. With these, we understand the fundamental materials' behavior and provide solutions to improve the properties or processing of the materials for various applications, such as predicting electronic & structural properties and modeling the chemical kinetics & equilibria to optimize a material processing route. At the macro-scale, Computational Fluid Dynamics allows us to design, model, and optimize all Mineral, Metals, & Materials Processes at the industrial scale.

Computational methods are becoming critical in all areas of science and engineering, such as Density-Functional Theory calculations and multiscale modeling, offering insights into material behaviors at the atomic, microscopic, and macroscopic scales. With these, we understand the fundamental materials' behavior and provide solutions to improve the properties or processing of the materials for various applications, such as predicting electronic & structural properties and modeling the chemical kinetics & equilibria to optimize a material processing route. At the macro-scale, Computational Fluid Dynamics allows us to design, model, and optimize all Mineral, Metals, & Materials Processes at the industrial scale.

|

|

|

|

|

||

| Kirk H. Bevan |

Raynald Gauvin |

Roderick I L Guthrie |

Jinhyuk Lee |

Jun Song |

Energy, Electronic, and Environmental Materials

Energy, electronic, and environmental materials refer to the classes of materials that are used in energy conversion/storage/harvesting devices (e.g., batteries, solar cells, supercapacitors, photocatalysts), electronic devices (e.g., semiconductor-based computer chips, light-emitting diodes, lasers), and environmental applications (e.g., sustainable processing, wastewater treatment, recycling). Designing these materials or processing routes requires a fundamental understanding of materials structure-properties-performance relationship for relevant applications. In our department, we use both experimental and computational approaches to accelerate the discovery of these materials.

Energy, electronic, and environmental materials refer to the classes of materials that are used in energy conversion/storage/harvesting devices (e.g., batteries, solar cells, supercapacitors, photocatalysts), electronic devices (e.g., semiconductor-based computer chips, light-emitting diodes, lasers), and environmental applications (e.g., sustainable processing, wastewater treatment, recycling). Designing these materials or processing routes requires a fundamental understanding of materials structure-properties-performance relationship for relevant applications. In our department, we use both experimental and computational approaches to accelerate the discovery of these materials.

|

|

|

|

|

|

|

||

| Kirk H. Bevan |

Marta Cerruti |

Richard Chromik |

George Demopoulos |

Raynald Gauvin |

Jinhyuk Lee |

Sidney Omelon |

||

|

|

|||||||

| Nathaniel Quitoriano |

Jun Song |

Materials Characterization

Materials characterization refers to the process by which a material’s structure and properties are probed and measured. It is a fundamental process in materials engineering, paramount to our scientific understanding of engineering materials. In our department we have expertise with many tools used to understand material composition, crystalline structure, microstructure, morphology, and electronic structure at different length scales, including scanning electron microscopes, X-ray diffractometers, X-ray tomography systems, and X-ray photoelectron spectrometers. The information gained with these tools is then used to design materials with improved properties and performance.

Materials characterization refers to the process by which a material’s structure and properties are probed and measured. It is a fundamental process in materials engineering, paramount to our scientific understanding of engineering materials. In our department we have expertise with many tools used to understand material composition, crystalline structure, microstructure, morphology, and electronic structure at different length scales, including scanning electron microscopes, X-ray diffractometers, X-ray tomography systems, and X-ray photoelectron spectrometers. The information gained with these tools is then used to design materials with improved properties and performance.

|

|

|

|

|

|

||

| Marta Cerruti |

Richard Chromik |

Raynald Gauvin |

Jinhyuk Lee |

Sidney Omelon |

Nathaniel Quitoriano |

Materials Process Engineering and Design

Materials processing and design involves planning and performing a series of chemical, thermal, and physical steps that involve making a starting material, form it into a shape, and then refine the structure and shape as needed. The goal of materials processing and design is to develop the features needed for the product to perform well in its intended application at a profitable cost and minimal adverse effect on the environment and human health. Our department achieves this by combining various advanced techniques, such as additive manufacturing, cold spraying, coatings, pyro- and hydro-chemical methods, endowing novel shapes and properties to materials for diverse applications.

Materials processing and design involves planning and performing a series of chemical, thermal, and physical steps that involve making a starting material, form it into a shape, and then refine the structure and shape as needed. The goal of materials processing and design is to develop the features needed for the product to perform well in its intended application at a profitable cost and minimal adverse effect on the environment and human health. Our department achieves this by combining various advanced techniques, such as additive manufacturing, cold spraying, coatings, pyro- and hydro-chemical methods, endowing novel shapes and properties to materials for diverse applications.

|

|

|

|

|

|

|||

| Mathieu Brochu |

Richard Chromik |

George Demopoulos |

Roderick I L Guthrie |

Sidney Omelon |

Philippe Ouzilleau |

|||

|

||||||||

| Stephen Yue |

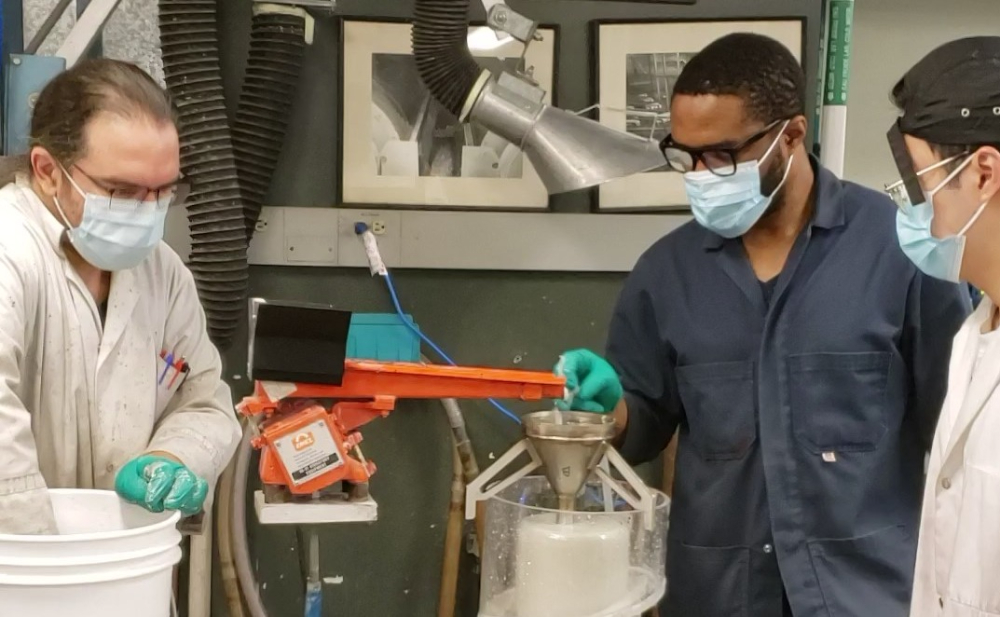

Mineral Processing and Extractive Metallurgy

Mineral processing and extractive metallurgy form a nexus within the material value chain by channelling mineral resources into global markets, supplying vital raw materials for construction and manufacturing. Our department, including both the materials and the mining sections, has expertise in all aspects of mining, mineral processing and extractive metallurgy, including laboratory experiments, computational modelling and state-of-the-art approaches to process design, process control and system integration. Current challenges include energy utilization, waste stream treatment, process decarbonization, and the sustainable supplying of so-called critical materials (lithium, cobalt, graphite, rare earth elements, etc.).

Mineral processing and extractive metallurgy form a nexus within the material value chain by channelling mineral resources into global markets, supplying vital raw materials for construction and manufacturing. Our department, including both the materials and the mining sections, has expertise in all aspects of mining, mineral processing and extractive metallurgy, including laboratory experiments, computational modelling and state-of-the-art approaches to process design, process control and system integration. Current challenges include energy utilization, waste stream treatment, process decarbonization, and the sustainable supplying of so-called critical materials (lithium, cobalt, graphite, rare earth elements, etc.).

|

|

|

|

|

| George Demopoulos |

Roderick I L Guthrie |

Sidney Omelon |

Philippe Ouzilleau |

Kristian Waters |

Structural Materials

This area focuses on the relationship between the structure of materials and their mechanical and chemical properties to understand how different materials perform in various load-bearing applications, such as automotive, aerospace, and biological applications. Structural materials include steels, magnesium alloys, aluminum alloys, concretes, and composites designed to be strong, light, formable, and endure extreme temperature and harsh chemical environments. To achieve this, various strategies, including alloying, texture engineering, and surface engineering, are employed, tailoring the properties of materials’ bulk and surface structure.

This area focuses on the relationship between the structure of materials and their mechanical and chemical properties to understand how different materials perform in various load-bearing applications, such as automotive, aerospace, and biological applications. Structural materials include steels, magnesium alloys, aluminum alloys, concretes, and composites designed to be strong, light, formable, and endure extreme temperature and harsh chemical environments. To achieve this, various strategies, including alloying, texture engineering, and surface engineering, are employed, tailoring the properties of materials’ bulk and surface structure.

|

|

|

|

|

|

| Mathieu Brochu |

Richard Chromik |

Roderick I L Guthrie |

Mihriban Ozden Pekguleryuz |

Jun Song |

Stephen Yue |