McGill scientists develop cleaner, cheaper way to make lithium-ion batteries

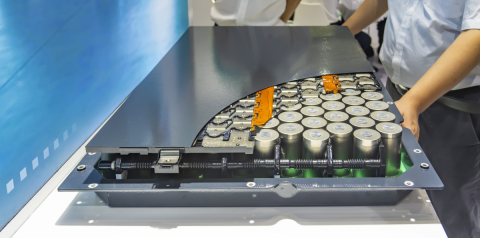

A team of McGill University researchers, working with colleagues in the United States and South Korea, has developed a new way to make high-performance lithium-ion battery materials that could help phase out expensive and/or difficult-to-source metals like nickel and cobalt.

The team’s breakthrough lies in creating a better method of producing “disordered rock-salt” (DRX) cathode particles, an alternative battery material. Until now, manufacturers struggled to control the size and quality of DRX particles, which made them unstable and hard to use in manufacturing settings. The researchers addressed that problem by developing a method to produce uniformly sized, highly crystalline particles with no grinding or post-processing required.

“Our method enables mass production of DRX cathodes with consistent quality, which is essential for their adoption in electric vehicles and renewable energy storage,” said Jinhyuk Lee, the paper’s corresponding author and an Assistant Professor in the Department of Mining and Materials Engineering.

The researchers say the findings, published in Nature Communications, offer a promising path toward more sustainable and cost-effective lithium-ion batteries, a critical component in the global shift to electrified transportation and the use of renewable power.

A materials breakthrough

The researchers devised a two-step molten salt process to synthesize the DRX particles. Molten salt enables better control over particle formation, improving quality and efficiency. First, the researchers promoted nucleation (the formation of small, uniform crystals) of the particles, and then limited their growth. This allowed them to produce battery-ready particles that are smaller than 200 nanometres, a size considered important for unlocking these materials’ performance in lithium-ion batteries.

“We developed the first method to directly synthesize highly crystalline, uniformly dispersed DRX single particles without the need for post-synthesis grinding,” said Lee. “This morphological control enhances both battery performance and the consistency of large-scale DRX cathode production.”

When tested in battery cells, the new materials maintained 85 per cent of their capacity after 100 charge-discharge cycles. That’s more than double the performance of DRX particles produced using older methods.

From lab to industry

The research was carried out by a McGill team in collaboration with scientists at Stanford University’s SLAC National Accelerator Laboratory and the Korea Advanced Institute of Science and Technology (KAIST). It was supported in part by Wildcat Discovery Technologies, a U.S.-based battery company interested in scaling DRX technologies for commercial use.

The team’s method could also make the process more scalable and energy efficient, addressing a key hurdle to the widespread adoption of DRX cathodes. Given the global demand for batteries, that could have a major ripple effect.

“Acceptance of our work highlights both the fundamental insight and industrial potential of the method,” said Hoda Ahmed, the lead author of the paper and a PhD student in McGill’s Department of Materials Engineering. “It shifts the field toward scalable manufacturing.”

With this synthesis strategy, the researchers say the door is now open to next-generation lithium-ion batteries that are more sustainable, more affordable, and easier to produce at scale.

About the study

"Nucleation-promoting and growth-limiting synthesis of disordered rock-salt Li-ion cathode materials," by Hoda Ahmed, Moohyun Woo, Raynald Gauvin, George Demopoulos, Jinhyuk Lee, and colleagues, was published in Nature Communications.

The research was funded by Wildcat Discovery Technologies and the Natural Sciences and Engineering Research Council of Canada.