Heat Transfer Laboratory

Director:

Professor B. Rabi Baliga

Members

Nirmalakanth (Nirma) Jesuthasan (Ph.D. student) Alexandre Lamoureux (Ph.D. student)

Samer Afara (M.Eng. Thesis student; co-supervised by Prof. L. Mydlarski)

Brandon Tulloch (M.Eng. Thesis student; co-supervised by Prof. L. Mydlarski)

Sylvain Bories (M.Eng. Thesis student)

Raul Palacios-Gamez (M.Eng. Thesis student)

Tihomir Sivov (M.Eng. Project student)

Location:

Room 54 Macdonald Engineering Building

Room 012 McConnell Engineering Building

Contact: Ms. Barbara Lapointe

Room 460 Macdonald Engineering Building

Tel.: (514) 398-6298

Summary of Research Program

The research program in this laboratory involves complementary numerical and experimental investigations of fluid flow and heat transfer phenomena encountered in engineering systems for energy conversion, exchange, and storage. Its main goals are the development of cost-effective mathematical models and numerical solution methods for the prediction of these phenomena and optimization of the aforementioned systems.

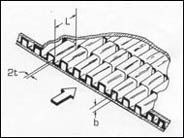

The emphasis in the numerical work is on the development and application of control-volume finite element methods (CVFEMs), for detailed simulations, and flow network modeling techniques, for system-level design. In particular, research is being carried out on the following topics: (i) unstructured adaptive-grid schemes based on algorithms for error estimation and minimization; (ii) simulations of fluid flow and heat transfer in porous media; (iii) simulation of unsteady flows and heat transfer in spatially periodic geometries; (iv) particle-tracking schemes for unstructured grids; (v) modeling of slurries of microencapsulated phase-change materials in liquids; (vi) flow network models of thermosyphons and loop heat pipes; (vii) simulation of fluid flow and and air-borne burning objects over forrested terrains; and (viii) integration of CVFEMs with thermal design optimization methods. Complementary experimental work is being undertaken to obtain accurate data that are useful for testing and refinements of the proposed cost-effective mathematical models and numerical solution methods. The experimental techniques used this laboratory include the following: (i) surface streamline, dye injection, and particle injection for flow visualization; (ii) thin gold-film heaters (about 80% transparent to visible light), liquid crystal sheets, and thermocouples for the measurement of local heat transfer coefficients; (iii) laser shadowgraphy; (iv) thermal anemometry; and (v) optical scanning, digitization, and image processing.

The motivation and ideas for this research are derived from needs in the following application areas: (i) industrial gas turbine engines; (ii) internally finned ducts; (iii) next-generation netbook computers; (iv) wind, solar, and geothermal energy systems; (v) materials processing techniques and systems; (vi) thermal energy storage and control systems; (vii) loop heat pipes; (viii) heat transfer enhancement; and (ix) control and mitigation of forest fires.

For a list of specific ongoing projects and collaborators, please see the section entitled Research Projects. Technical details are available in the papers listed under Sample Publications.

Photographs of some of the experimental set-ups in this laboratory are given in the remainder of this section.

Examples of Experimental Set-ups

Rig for Investigating Flow and Heat Transfer in Interrupted-Surface Ducts

|   |

Rig for Investigating Ice-Water Phase-Change Systems

|  |

Rig for Investigating Heat Transfer Through Semitransparent Cylindrical Radiation Shields