PhD candidate

Project: SNAP RTM Modelling for Automotive Application

LinkedIn sidharth.sarojininarayana [at] mail.mcgill.ca (Mail)

Supervisor: Prof Pascal Hubert

Fiber reinforced polymer matrix composites have been increasingly used in transportation industry due to their light weighting properties. The mass production of parts made from these materials have not been possible due to higher cycle times of the traditional composite manufacturing processes. Recent development of fast cure resins has opened the door for large scale production of high performance polymer composites. However, manufacturing of molded parts poses a great challenge due to high reactivity of the resin and its application in transportation sector is still at an early stage.

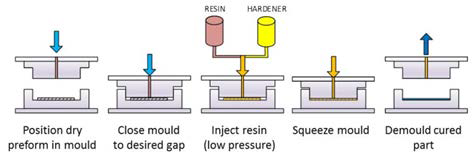

In this project, we use a variant of resin transfer molding process (RTM) which is the most common process used for manufacturing automotive parts. Its called SNAP (Short Novel Affordable Process) RTM which is Compression-RTM process. The goal of this project is to develop a process model which takes into account all the physical phenomena that take place during the entire SNAP-RTM process cycle. The main approach used in process modelling is to divide the process into sub-models and study each phenomena individually. A finite element method (FEM) will be used to solve the governing equation in each model. The existing process simulation tools will also be modified to take into account the dynamic behavior of these resins and new physical models of these materials will be developed. This project aims to solve these manufacturing problems, to develop robust, fast and efficient processes for manufacturing high-performance composite parts and to develop tools to model and predict these manufacturing processes.