Welcome to the Structures and Composite Materials Laboratory in the Department of Mechanical Engineering at McGill University.

The understanding of composite materials and their structures requires an in-depth knowledge of basic material behaviour. Knowledge of fibre and resin behaviour is essential for understanding the intricacies of composite manufacturing processes. This must be accompanied by stress, strain and failure analysis in both the static and fatigue regimes. Finally, designs must be manufactured and tested. Here is where design optimization helps to achieve the final goal: a successfully designed composite structure. The McGill Structures and Composite Materials Laboratory thus explores the design of composite materials and their structures “From Start to Finish”.

The SCML is a proud and active member of CREPEC, the Research Center for High Performance Polymer and Composite Systems. Based in the Québec province, the organism gathers many researchers from universities as well as technical centers.

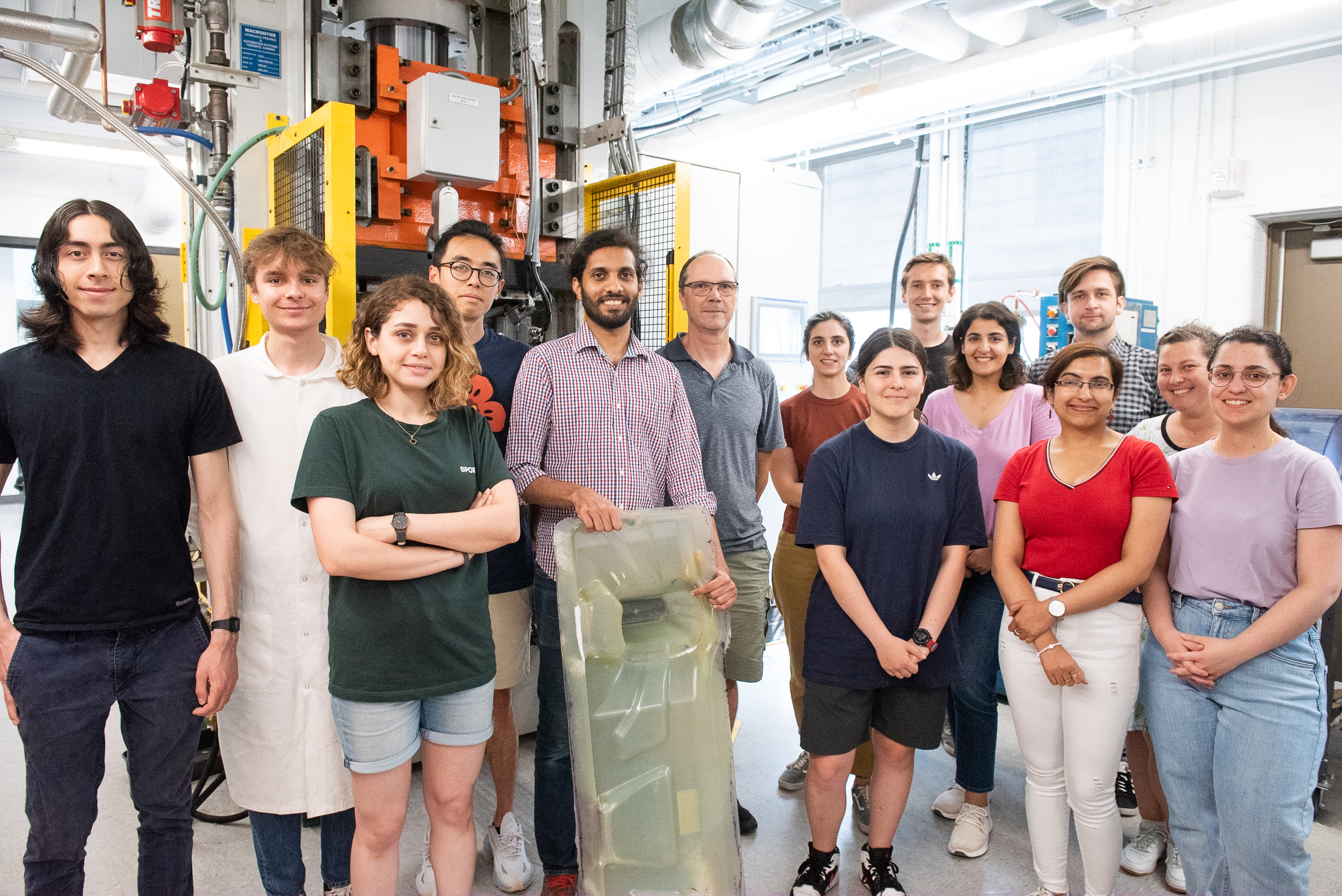

Composites Lab SURE students - Summer 2023

The McGill Composites Lab acknowledges that the work and research we do take place in Tiohtià:ke/Montréal, on the unceded Indigenous lands of the Kanien'kehá:ka/Mohawk Nation.

Le laboratoires des composites de McGill reconnait que le travail et la recherche que nous effectuons se déroulent à Tiohtià: ke / Montréal, sur les terres autochtones non cédées de la nation Kanien’kehá: ka / Mohawk.