The Structure and Composite Materials Laboratory (SCML) can assume a wide range of experiments.

From characterizing a material to testing its mechanical properties, the equipment available in the lab allow complete studies of a material.

From characterizing a material to testing its mechanical properties, the equipment available in the lab allow complete studies of a material.

The full list of tools of the SCML can be found on the CREPEC website.

Materials Characterization

| Equipement | What for? | Specifications |

|---|---|---|

|

DSC 25 (TA Instruments) |

Glass transition temperature , Fusion, Crystallization, Heat of reaction, Degree of cure |

Temperature: -90C to 400C (coupled with the cooling unit RCS90) Samples size: 5 to 15mg Modulation available |

|

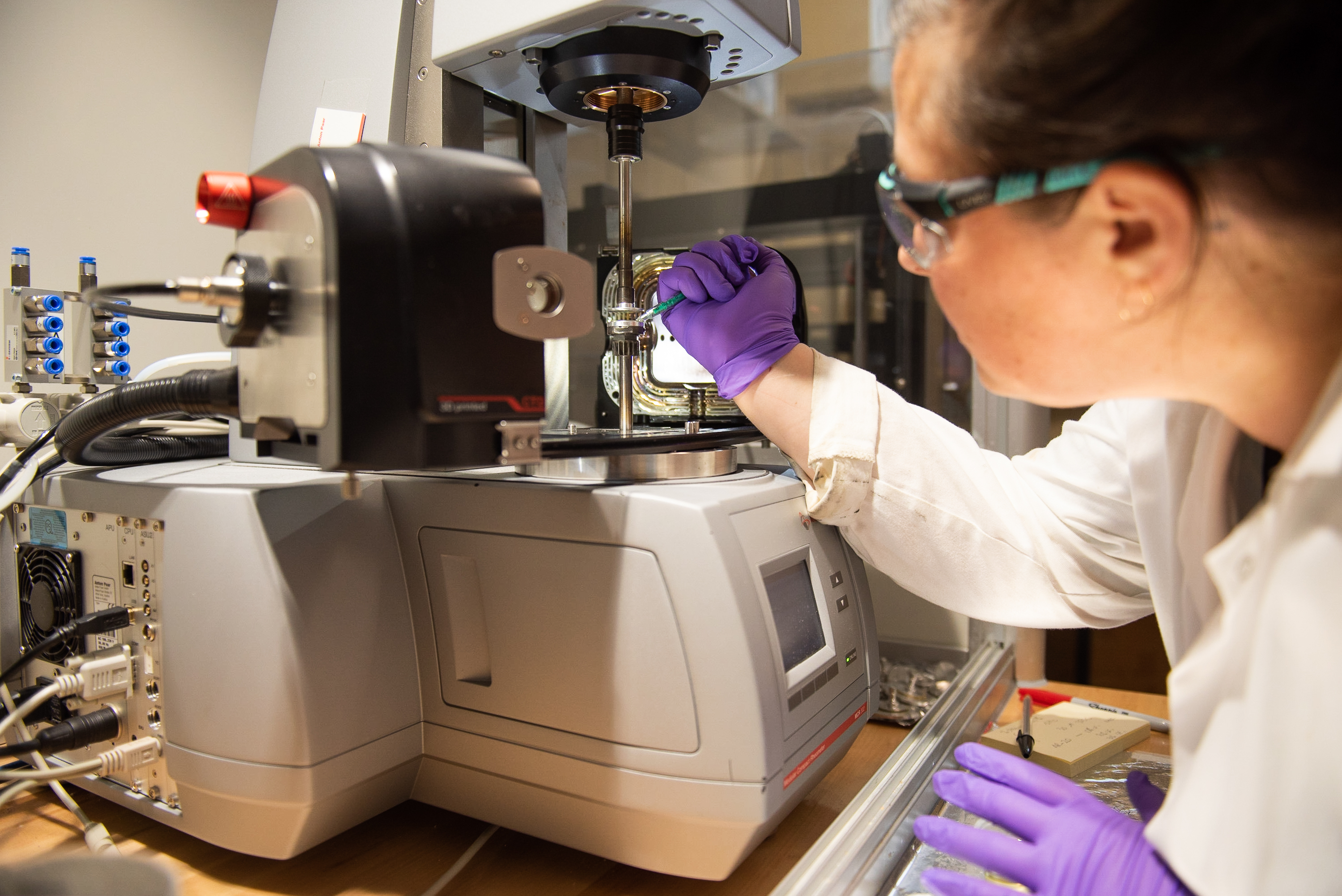

Rheometer MCR 302 (Anton Parr) |

Viscosity, Shrinkage |

Temperature (with ETC): 25C to 600C Fixtures Available: Parallel plates ɸ25mm & ɸ40mm, torsion |

|

DSC Q100 (TA Instruments) |

Glass transition temperature, Fusion, Crystallization, Heat of reaction, Degree of cure |

Temperature: -70C to 400C (coupled with the cooling unit RCS90) Samples size: 15mg Modulation available |

|

DMA Q800 (TA Instruments) |

Loss and Storage Modulus behavior, Glass transition temperature |

Temperature: 25C to 600C (-90C with the external liquid nitrogen tank) Clamps available: Dual & Single Cantilever, 3 pt bending, compression, film & fibre tension |

|

TMA Q400 (TA Instruments) |

Expansion Coefficient, Glass transition temperature |

Temperature: 25C to 700C (-70C with the cooling unit RCS90) Probes available: Penetration, MacroExpansion, Expansion |

|

TGA Q500 (TA Instruments) |

Degradation temperature |

Temperature: 25C to 1000C Samples size: up 100mg |

| Permeability fixture |

Transverse Permeability |

Room Temperature Sample: ɸ3in |

| Microscopy |

Visual observation of samples characteristics (voids, phases, interfaces, particules distribution, sizing, etc...) |

Objectives x5—x50 Mosaic creation available with the automatic stage |

Mechanical Testing

| Equipement | What for? | Specifications |

|---|---|---|

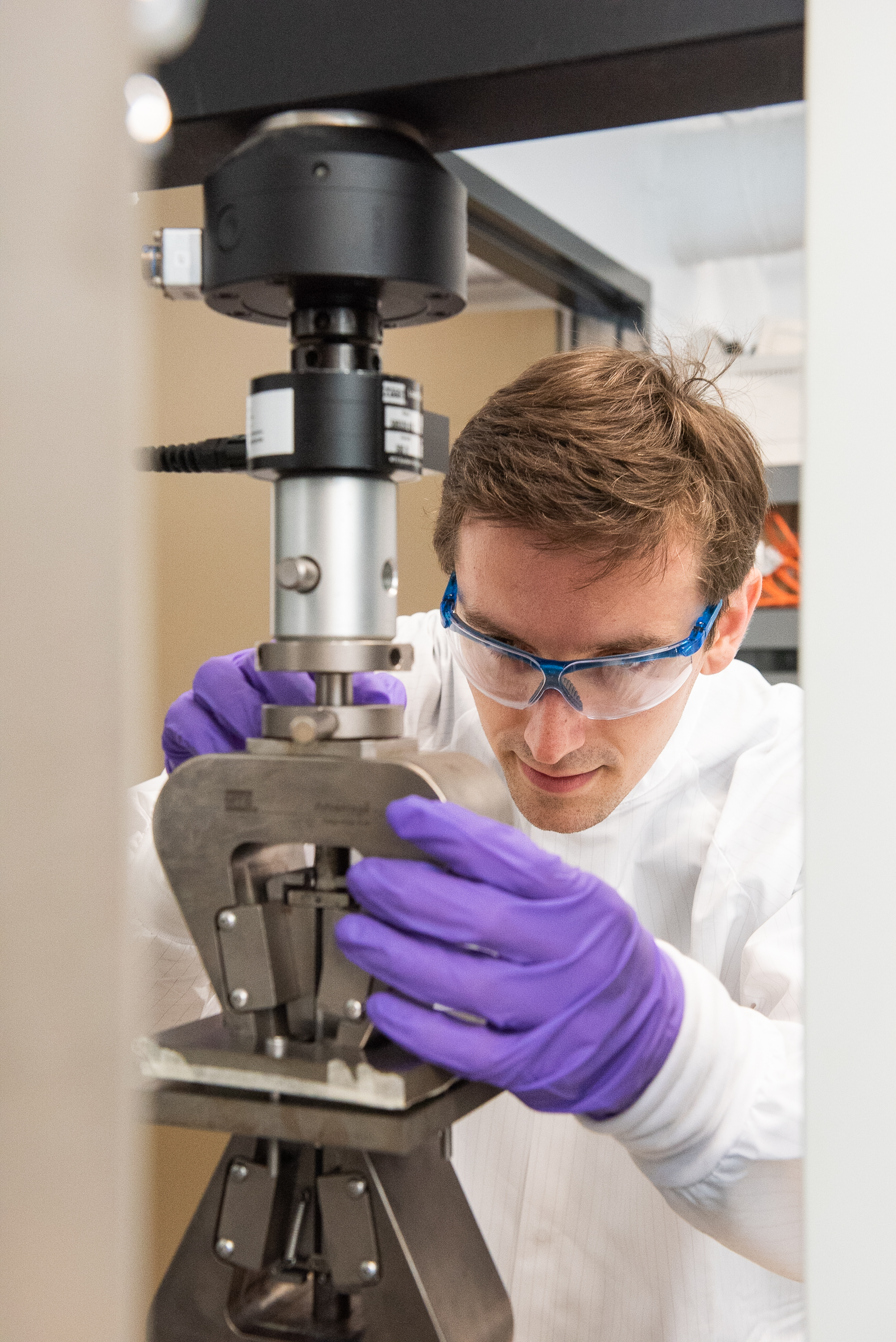

| MTS 5kN | Tensile tests, 3 & 4 point-bending, Curved beam, Peel test, Iosipescu shear test, Compression |

Load Cell: 5kN, 500N Environmental Chamber available (Temperature) |

|

MTS 100kN |

Tensile tests, 3 & 4 point-bending, Compression |

Load Cell: 100kN Environmental Chamber available (Temperature + Humidity) |

|

MTS 250kN |

Tensile tests, 3 & 4 point-bending, Compression, Sample molding |

Load Cell: 250kN |

Processing

| Equipement | What for? | Specifications |

|---|---|---|

| Macrodyne Press | Part Manufacturing, Sample molding |

Temperature: 25C to 250C (water cooling) 250 tons Different molds available Addition of heating cartridges to the mold or vacuum possible |

| Aon 3D Printer | Part Manufacturing |

Temperature: up to 200C Printing size :450 x 450 x 640 mm Conditioning cabinet available |

| Prusa i3 MK3S+ 3D Printer | Part Manufacturing |

Temperature: up to 300C Printing size : 25×21×21 cm Conditioning cabinet available |

| Blue M Oven - Big Chamber | Curing, Drying |

Temperature: 25 to 200C |

|

Blue M Oven - Small Chamber (*2) |

Curing, Drying |

Temperature: 25 to 200C 25in x 20in x 20in |

|

Secotom 50 |

Cutting |

Cutting capacity: 165 x 50 mm Rotational Speed: 300 - 5000 rpm Diamond cutting blade specific to materials |

For any inquiry or future project please contact lucie.riffard [at] mcgill.ca (Lucie Riffard).